DESIGN FOR Recycling

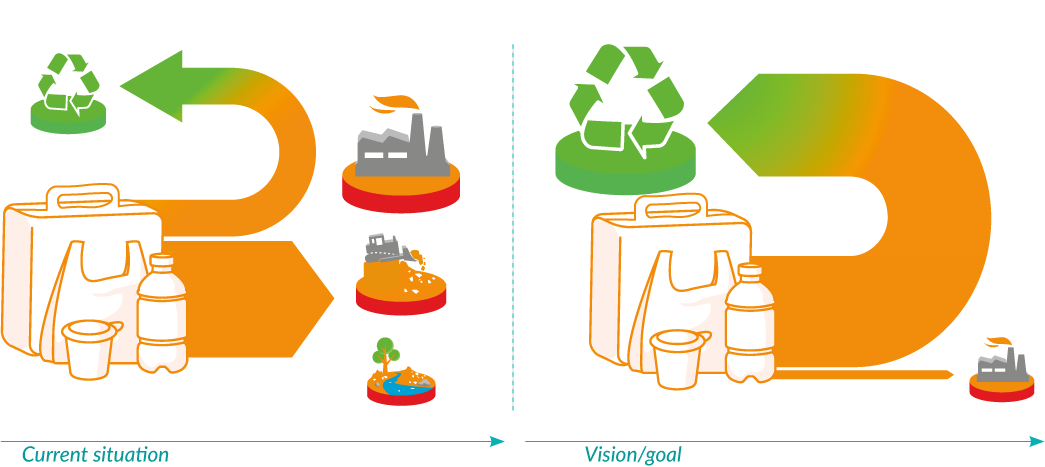

When packaging reaches the end of its life, it is preferable – from an environmental perspective – to reuse the resources invested during its production for maximum benefit and not simply dispose of the packaging.

Design for recycling aims at facilitating the Recovery of the packaging materials for additional use. Among other environmental benefits such as reducing the consumption of fossil resources, this makes a significant contribution towards lowering the release of greenhouse gas emissions, which are responsible for climate change.

If a remaining part of packaging cannot be recycled in the existing conditions of the recycling infrastructure, the energy (calorific value) included in this should at least be recovered for heating or other energy supply.

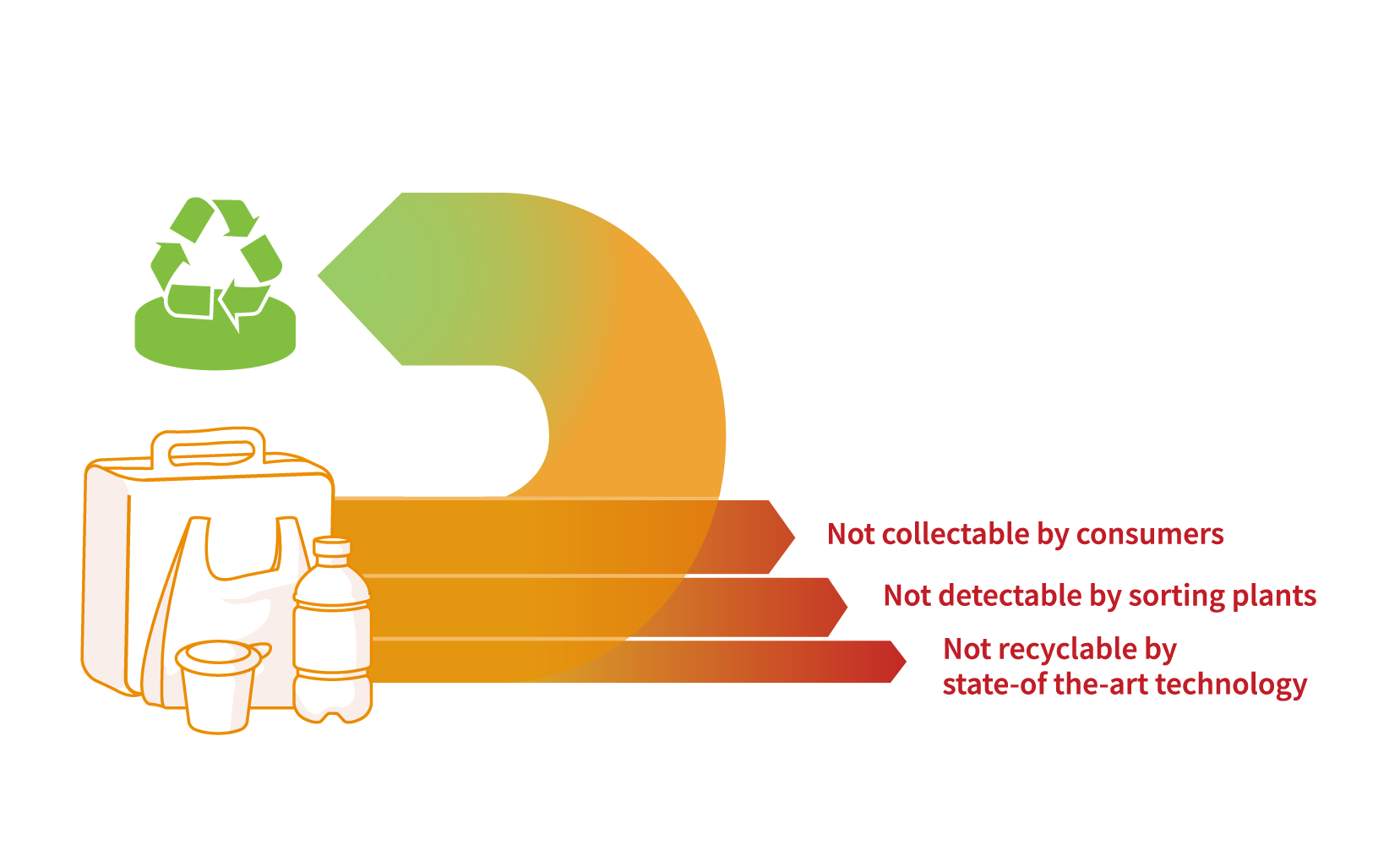

One prerequisite for effective plastic packaging recycling is the existence of a well-established Waste Collection and recycling infrastructure with sorting of plastic packaging for subsequent appropriate Treatment. However, “recycling-ready” packaging designs may stimulate investment in the collection, sorting and recycling infrastructure even in countries where such infrastructure is still lacking today.

A policy framework has been established in the European Union that aims to ensure the proper implementation of such waste collection and treatment infrastructures supporting the ultimate goal of a Circular Economy that “closes the loops” of product and material life cycles and covers packaging as well as all products.

Design for recycling allows existing potential to be exploited in order to increase recycling rates and close loops.

OPTIMISATION APPROACHES