How to Approach Eco Design Optimisation

ECO DESIGN OPTIMISATION IS JUST ONE ELEMENT IN THE COMPLEX PACKAGING DESIGN PROJECTS

Based on the understanding of Eco Design as a further key requirement of equal importance, developing and implementing of an Eco Design Strategy must become an integral part of the entire management of packaging design and the relevant decision-making processes in the company. Senior management decisions must form the foundation for this integrated implementation of Eco Design.

When packaging projects are implemented in practice, however, environmental optimisation has to be undertaken in parallel with many other optimisation efforts made in other requirement areas. This means that repeated reviews of potential environmental improvements are normally necessary since the initial versions of the packaging change during the course of the project due to optimisation work carried out in other requirement areas.

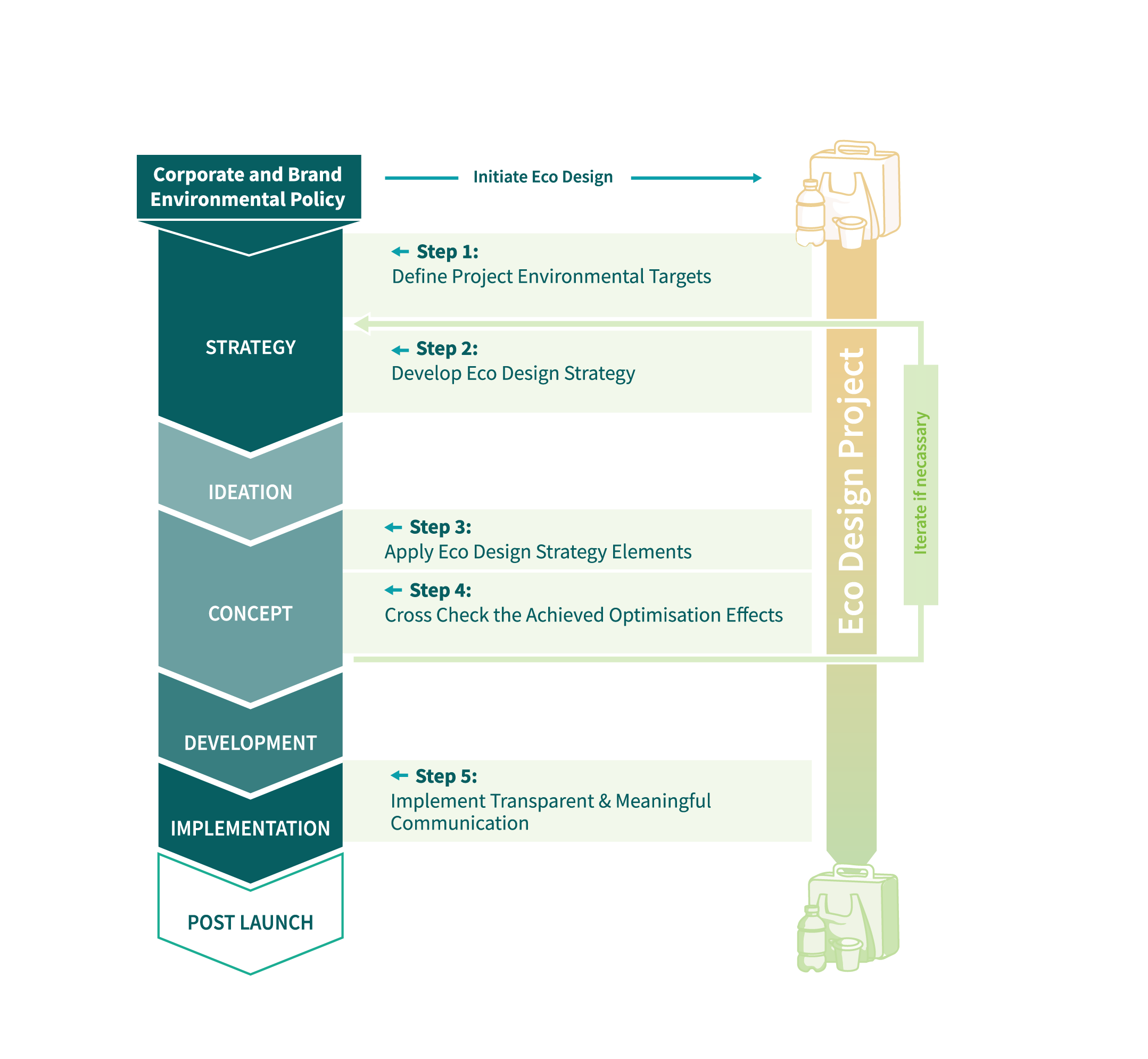

The following diagram shows the parallel nature of the various optimisation processes.

INTEGRATION OF ECO DESIGN PROCEDURES INTO THE MANAGEMENT PROCESS

The integration of Eco Design in the management process of a specific Packaging Project then involves the following five steps as a minimum.

The steps performed and decisions taken for each Eco Design project must be documented systematically to support the continuous improvement of internal procedures as well as transparent and reliable communication with customers.

The integration of Eco Design in the management process of a specific packaging project then involves the following five steps as a minimum.

The steps performed and decisions taken for each Eco Design project must be documented systematically to support the continuous improvement of internal procedures as well as transparent and reliable communication with customers.

The following diagram illustrates how these five steps of Eco Design correspond to a typical stage-gate process of a packaging design project.

HANDLING CONFLICTING ENVIRONMENTAL TARGETS

During a packaging Eco Design project, there may be conflicts among the different optimisation approaches. Whereas in some cases the optimisation of different environmental aspects go hand-in-hand, in other cases optimising one environmental aspect may have adverse effects on another (e.g. weight reduction versus recyclability). In such cases, trade-offs need to be sought by management.

Life cycle assessments (LCAs) can make it easier to compare different packaging options with regard to defined Environmental impact categories such as climate change potential or resource consumption. However, the limits of life cycle assessments must be taken into consideration here. For instance, littering is unquestionably an important environmental impact, but it is not covered by life cycle assessments and therefore has to be considered separately. Also, the results of LCA tools may only be valid for a certain geographical area.

Furthermore, the minimisation of environmental impacts by Eco Design remains a multidimensional target. Since the various environmental impacts do not represent a predefined and clearly hierarchical target system, there is no science-based approach for solving conflicts resulting from burden shifting from one impact area to another (e.g. climate change versus loss of biodiversity).

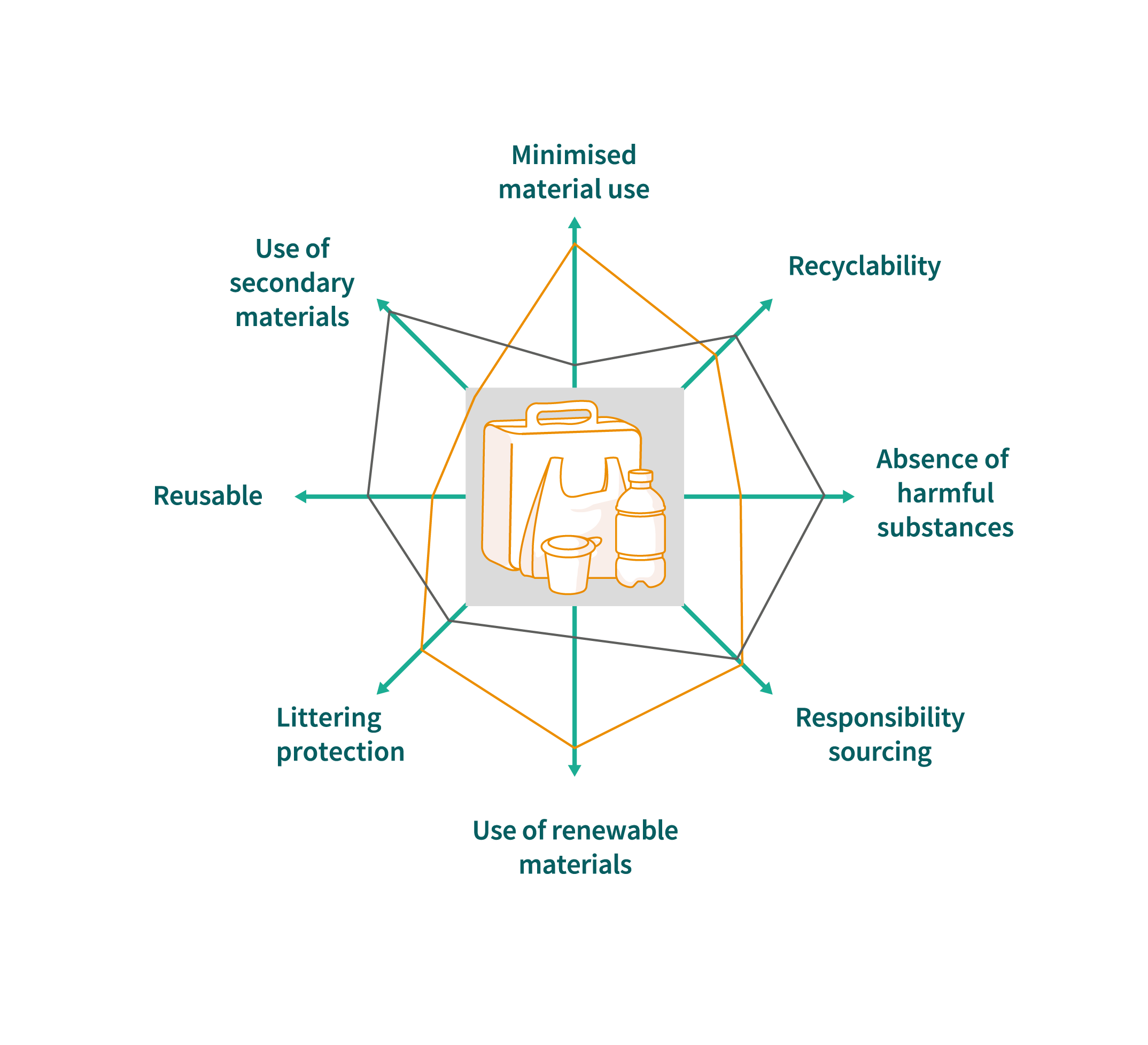

Within the Eco Design process, conflicting objectives must, however, be made transparent and ‘resolved’ through appropriate decisions referring to the priorities set for the design project (see step 4 in the Eco Design process). Depending on the complexity, either a table or a spider chart can be used to create transparency and visualise the pros and cons of each design option.

In order to reduce the complexity of the decision-making, it is also useful to define minimum requirements for all relevant environmental targets while defining the environmental targets of the packaging project (see steps 1 and 2 of the management process).

As well as conflicts among different environmental targets, conflicts with the other key requirements, including, for instance, convenience, marketing functions or cost, may also occur within the Eco Design project. These conflicts can in principle be addressed in the same way as conflicts within the environmental domain.