DESIGN FOR OPTIMISED RESOURCE USE

Design for optimised resource use aims to reduce the amount of natural resources utilised for producing the packaging materials. At the same time, the amount of material entering the Waste stream at the end of their life is reduced, thus decreasing the environmental impacts.

Approaches to achieving a design for optimised resource use include

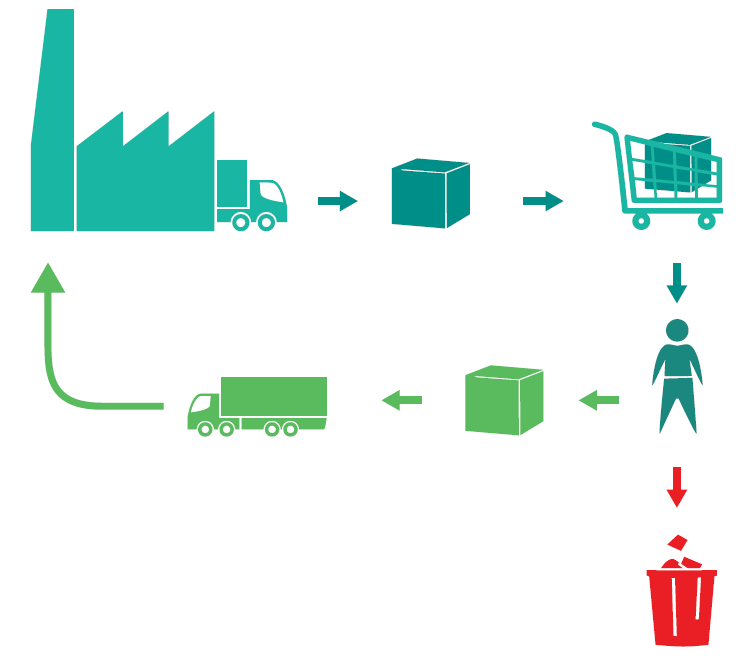

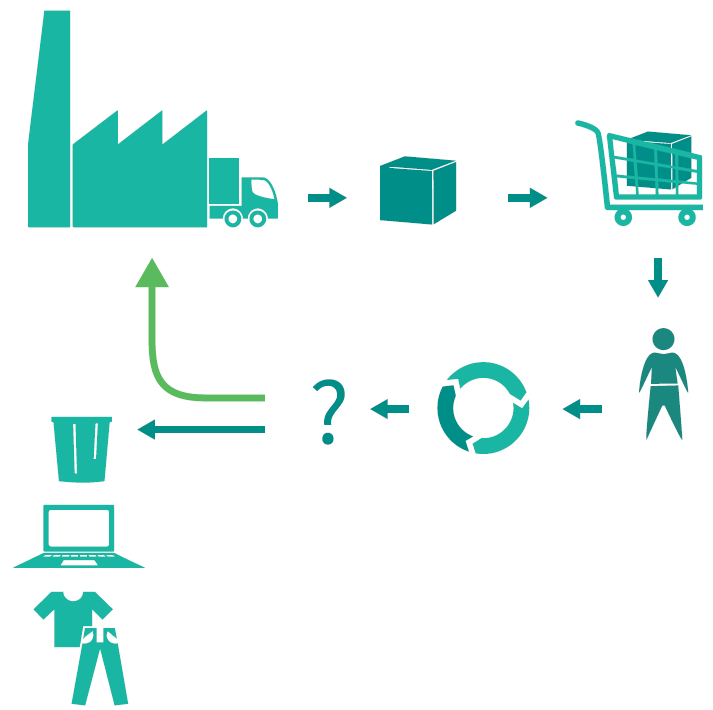

- Re-use solutions

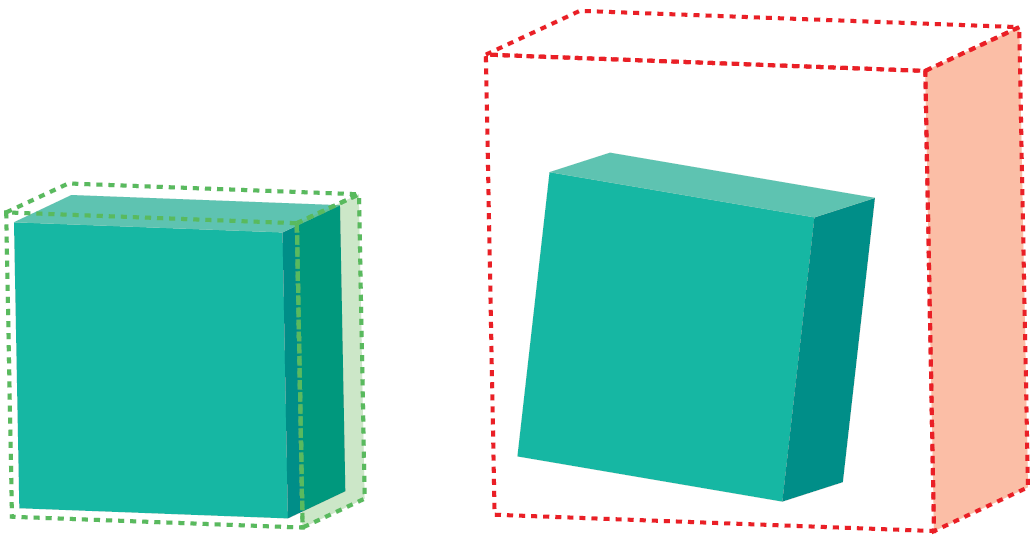

- Use less material

- Use of recycled material

- Use bio-based materials

Despite their differences, each of these different approaches ultimately addresses the same aspect: they minimise the impact on the environment from feedstock and packaging material production. This includes energy consumption and related CO2 emissions, the extensive use of natural resources and possible emissions of substances harmful to the environment.

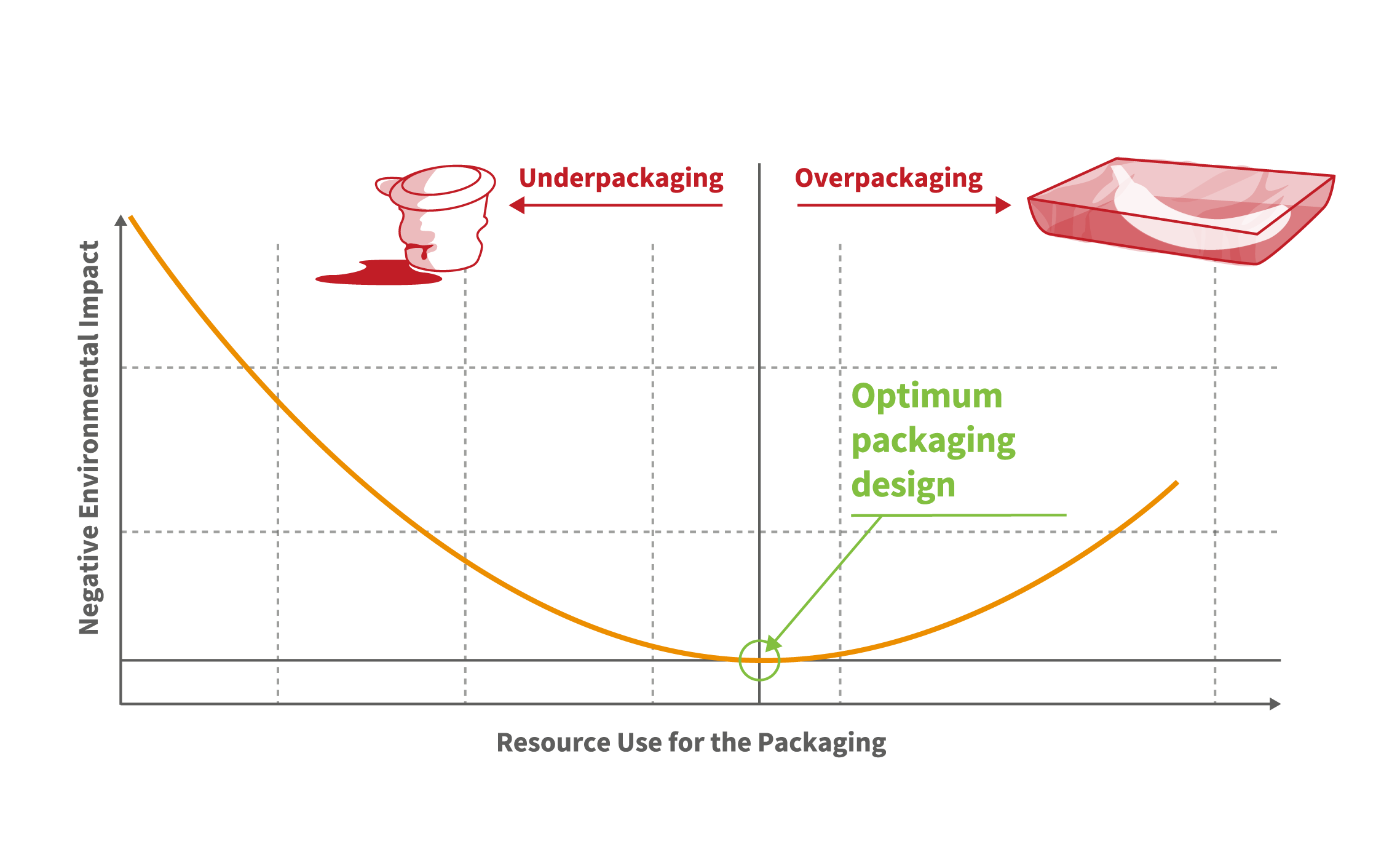

A balance between Overpackaging and Underpackaging needs to be found with regard to the protection of packed goods.

OPTIMISATION APPROACHES